XRF Web Seminar Module 2 – Basic XRF Concepts

2-1

Module 2:

Basic XRF Concepts

August 2008 2-1

Module 2 – Basic XRF Concepts XRF Web Seminar

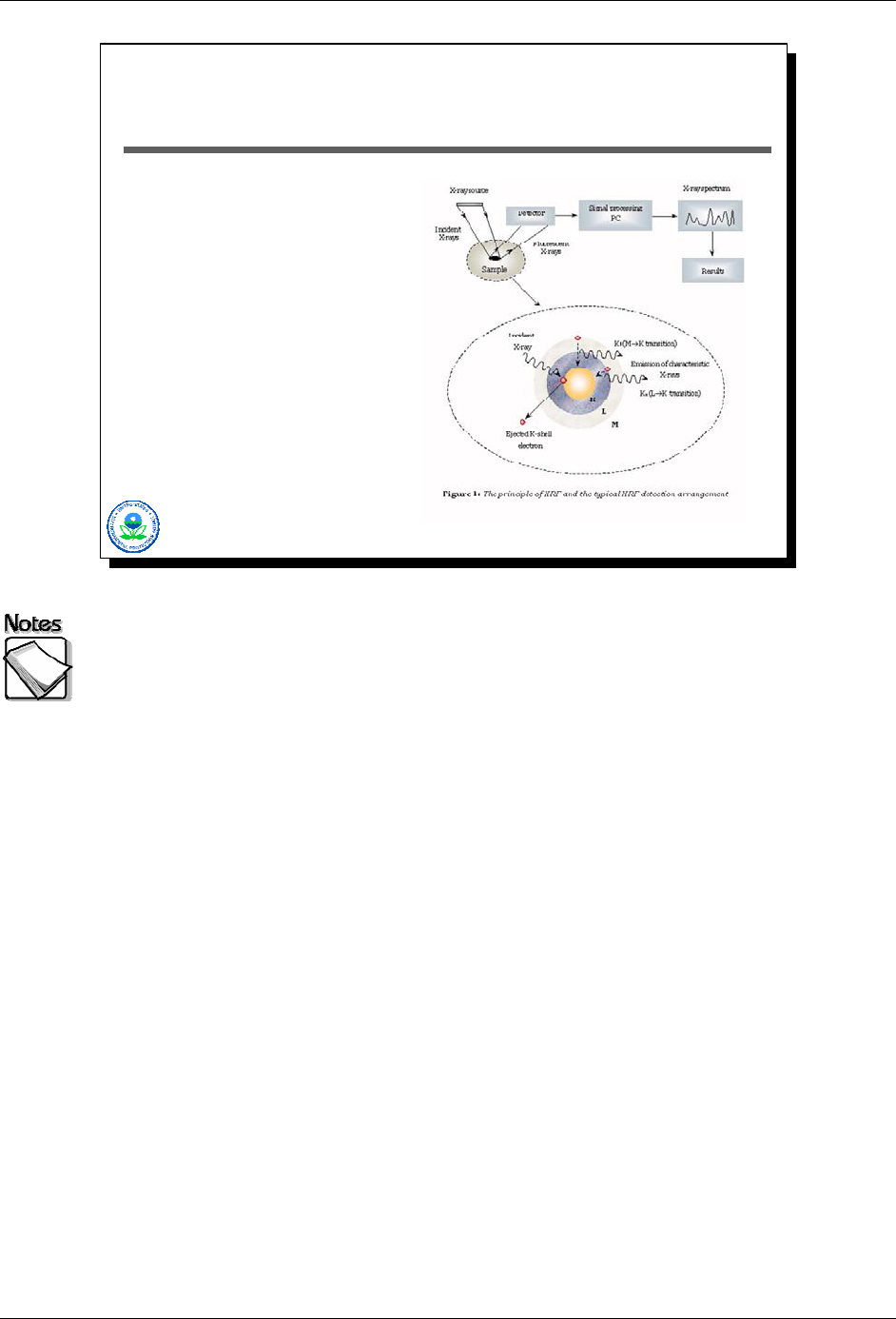

What Does An XRF Measure?

X-ray source irradiates

sample

Elements emit

characteristic x-rays in

response

Characteristic x-rays

detected

Spectrum produced

(frequency and energy

level of detect x-rays)

Concentration present

estimated based on

sample assumptions

Source: http://omega.physics.uoi.gr/xrf/english/images/PRINCIP.jpg

2-2

X-ray source irradiates sample: Modern XRF systems include basically three

components: an x-ray source, a detector, and a signal processing unit. The x-

ray source produces x-rays that irradiate the sample of interest. Traditionally x-

ray sources were sealed radionuclide sources such as Fe-55, Cd-109, Am-241,

or Cm-244. Each sealed source type emitted x-rays of a particular energy level.

The selection of a sealed source depended on the elements of interest, since

different elements respond best to different irradiating x-ray energy levels.

Sealed sources, however, presented practical challenges: some had relatively

short half-lives meaning that they had to be changed on a regular basis to

maintain XRF performance; they often required special licenses to be used; and

each only addressed a relative small set of inorganic contaminants of concern.

Consequently manufacturers of XRF units have been moving to electronic x-ray

tubes for producing the required x-rays.

Elements emit characteristic x-rays in response: When a sample is irradiated

with x-rays, the x-rays interact with individual atoms, and these atoms respond by

“fluorescing”, or producing their own x-rays whose energy levels and abundance

(number) are different for each element.

Characteristic x-rays detected: The XRF detector captures these fluorescent

x-rays, counting each and identifying their energy levels.

Spectrum produced (frequency and energy level of detect x-rays): The

signal processing unit takes the detector information and produces spectrum.

Additional software processing converts the spectrum into element-specific

estimates of the concentrations present.

August 2008 2-2

XRF Web Seminar Module 2 – Basic XRF Concepts

Concentration present estimated based on assumptions: Additional

software processing converts the spectrum into element-specific estimates of the

concentrations present based on sample assumptions.

August 2008 2-3

Module 2 – Basic XRF Concepts XRF Web Seminar

2-3

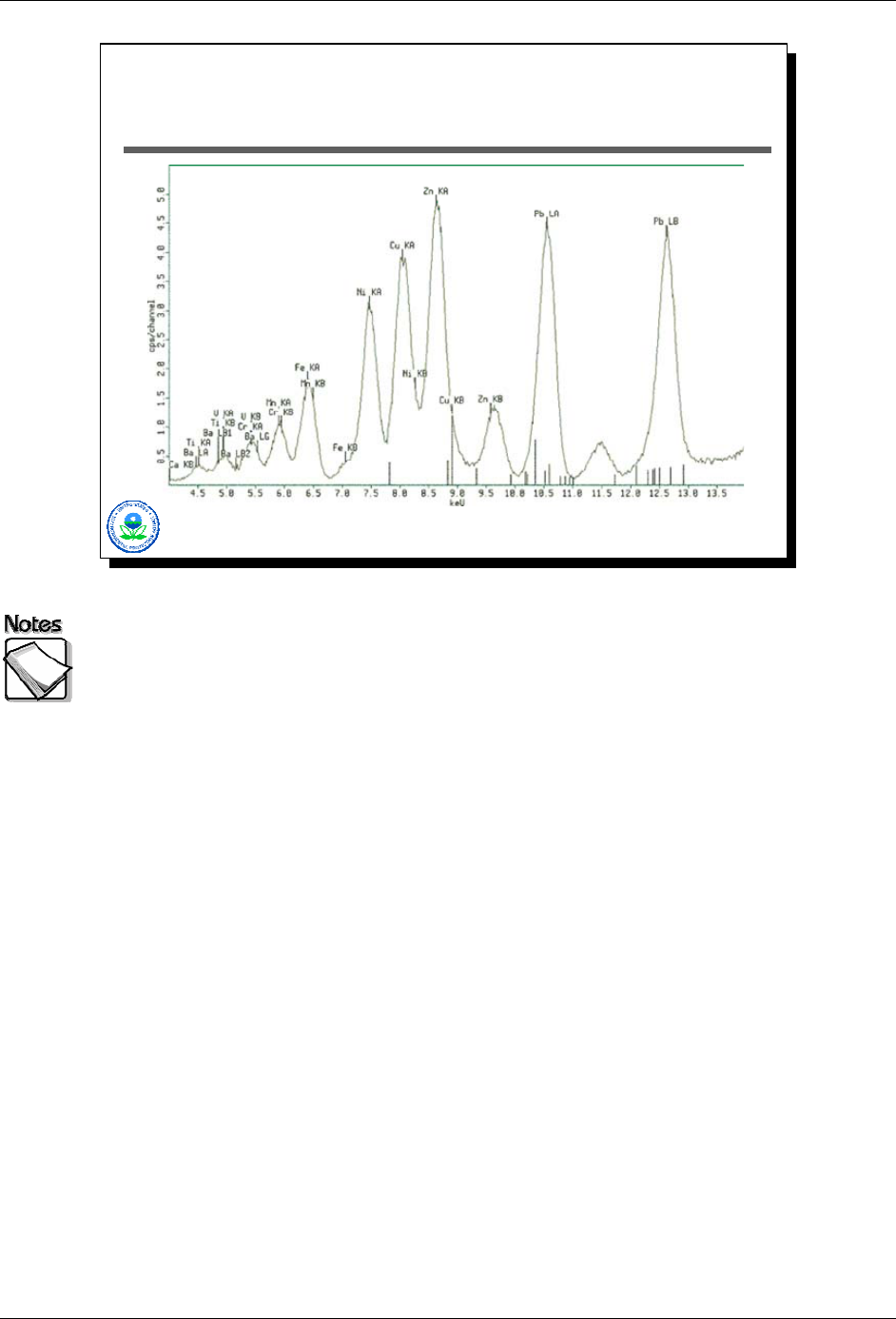

Example XRF Spectra

This slide shows an example of an x-ray spectra produced by an XRF

measurement. The x-axis is x-ray energy, and the y-axis shows the number of x-

rays observed at each energy level. The peaks are indicative of the presence of

unique elements. The heights of the peaks are proportional to the number of x-

rays counted, which in turn is proportional to the mass of the element present in

the sample. The width of the peaks, in general, is an indication of the detector’s

ability to “resolve” x-ray energies it observes, or in other words, to correctly

identify the energy level of the x-ray it detected. The better the resolution, the

tighter these peaks will be, the better the XRF will be in terms of performance

(i.e., correctly identifying and quantifying the presence of a particular element).

This spectrum has a couple of features of interest. As this spectrum

demonstrates, any particular element can have more than one peak associated

with it, for example lead, or zinc, or iron in this spectrum. As this spectrum also

demonstrates, peaks for individual elements may be so close that for all practical

purposes they are indistinguishable. The Fe/Mn peak around 6.5 KeV is a good

example. This is what causes what is known as interference, which is something

that will be discussed later.

August 2008 2-4

XRF Web Seminar Module 2 – Basic XRF Concepts

2-4

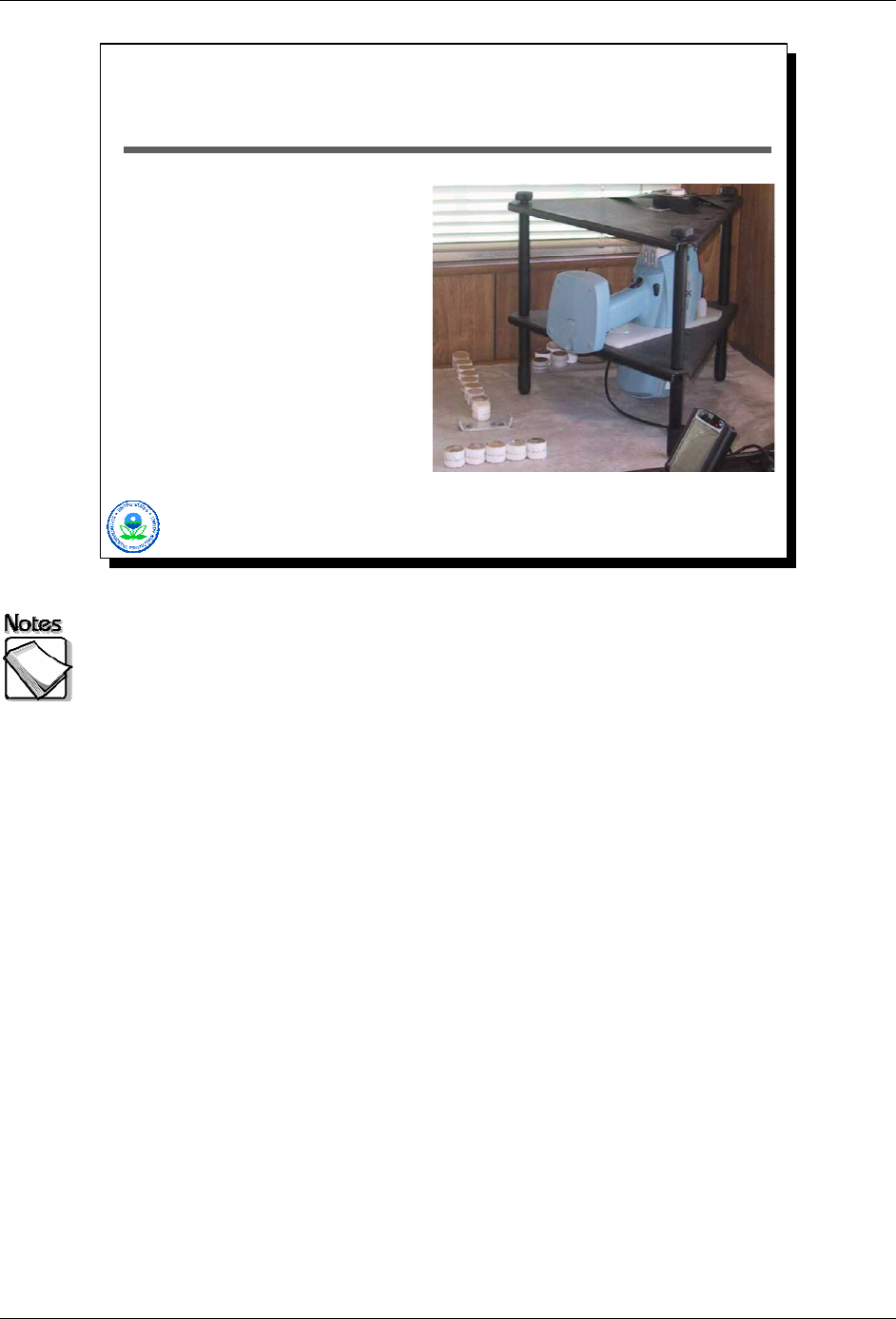

Bench-top XRF

This slide shows a bench-top XRF unit. Samples from the field are brought to

the unit which can be located in a trailer. XRF is a well-established analytical

technique with a long history of use in a laboratory environment. In the last

decade advances in electronics have allowed the development and refinement of

field-deployable units. XRF analysis is different from most other inorganic

techniques in that it is a non-destructive analysis. In other words, the original

sample is not destroyed by the analytical process. There are no extraction or

digestion steps. Consequently the same material can be analyzed repeatedly by

an XRF unit, or analyzed by an XRF unit and then submitted for some other

analysis.

August 2008 2-5

Module 2 – Basic XRF Concepts XRF Web Seminar

How is an XRF Typically Used?

Measurements on

prepared samples

Measurements

through bagged

samples (limited

preparation)

In situ measurements

of exposed surfaces

(continued)

2-5

Measurements on prepared samples: The XRF can be used to take

measurements on samples that are prepared by drying and grinding. The

sample measured consists typically of a few grams of soil contained in a special

cup designed for XRF use.

Measurements through bagged samples (limited preparation): The XRF can

also be used to take measurements on bagged samples that have undergone

very little preparation.

In situ measurements of exposed surfaces: The XRF can also be used to

take measurements of exposed surfaces in the field. Only surface

measurements can be made using this method.

August 2008 2-6

XRF Web Seminar Module 2 – Basic XRF Concepts

How is an XRF Typically Used?

Measurements on

prepared samples

Measurements

through bagged

samples (limited

preparation)

In situ measurements

of exposed surfaces

2-6

Measurements on prepared samples: The XRF can be used to take

measurements on samples that are prepared by drying and grinding. The

sample measured consists typically of a few grams of soil contained in a special

cup designed for XRF use.

Measurements through bagged samples (limited preparation): The XRF can

also be used to take measurements on bagged samples that have undergone

very little preparation.

In situ measurements of exposed surfaces: The XRF can also be used to

take measurements of exposed surfaces in the field. Only surface

measurements can be made using this method.

August 2008 2-7

Module 2 – Basic XRF Concepts XRF Web Seminar

What Does an XRF Typically Report?

Measurement date

Measurement mode

“Live time” for measurement acquisition

Concentration estimates

Analytical errors associated with estimates

User defined fields

2-7

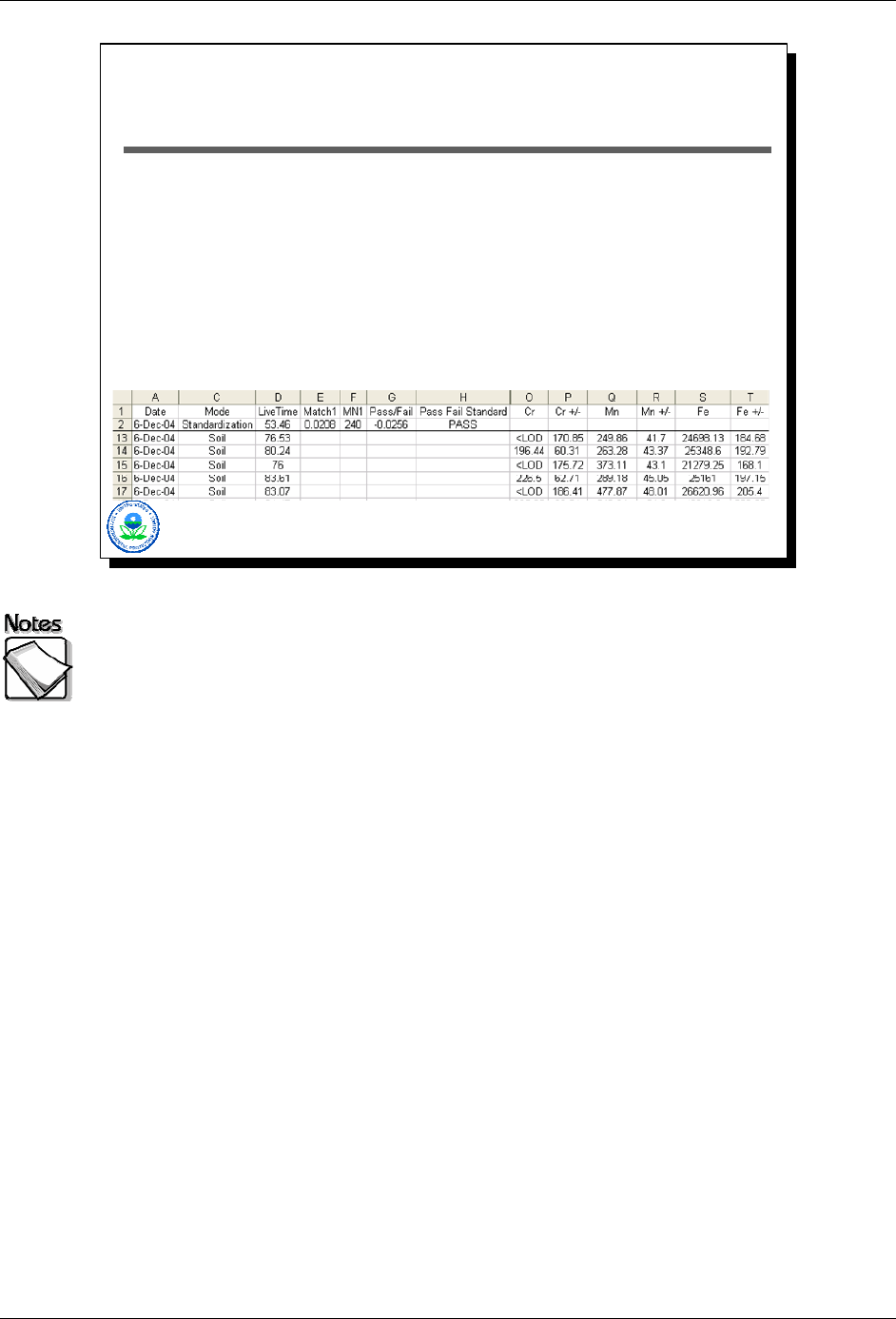

What does an XRF typically report: The following items are typically reported

by the XRF:

» Measurement date

» Measurement mode – which includes the type of sample measured

» “Live time” for measurement acquisition – which indicates the number of

seconds the detector was actually collecting information. This is a subtle but

important point. In the case of Innov-X instruments, a measurement time is

selected and the measured acquired for that duration. The live time for an

Innov-X unit is something less (typically 80%) than the measurement time. In

contrast, for a Niton instrument the measurement time selected by the user

corresponds to the live time, and consequently a Niton measurement will

actually take longer than specified measurement time (typically around 20%

longer).

» Concentration estimates. Consistent with SW846 Method 6200, a “<LOD” is

typically reported when the measured result is less than 3 times the standard

deviation for that measurement as estimated by the instrument. For both

Niton and Innov-X, the software can be set to force the instrument to report

measured values no matter their error. The pros and cons of doing this will

be discussed later.

August 2008 2-8

XRF Web Seminar Module 2 – Basic XRF Concepts

» Analytical errors associated with estimates. Two important notes here. In the

case of an Innov-X unit, the reported error is an estimate of the one standard

deviation error associated with the reported value. In the case of a Niton unit,

the reported error is actually twice the estimated standard deviation error

associated with the measurement. For both instruments, if a <LOD is

reported as a result, the error column will contain the estimated detection limit

for that measurement rather than the error. The estimated detection limit is

three times the error. One can see this in the case of Cr. The first

measurement reports Cr as an <LOD with a detection limit of 170 ppm. The

second measurement reports Cr as 196 ppm with an error that is

approximately a third of the detection limit reported by the previous

measurement.

» User defined fields – which may include comparison to a certain

concentration

August 2008 2-9

Module 2 – Basic XRF Concepts XRF Web Seminar

Which Elements Can An XRF

Measure?

Generally limited to elements with atomic number

> 16

Method 6200 lists 26 elements as potentially

measurable

XRF not effective for lithium, beryllium, sodium,

magnesium, aluminum, silicon, or phosphorus

In practice, interference effects among elements

can make some elements “invisible” to the

detector, or impossible to accurately quantify

2-8

Generally limited to elements with atomic number > 16: The XRF is

generally limited to elements which have an atomic number greater than 16.

However, the XRF cannot necessarily measure all elements with an atomic

number greater than 16 at concentrations that would be considered acceptable

for environmental applications.

Method 6200 lists 26 elements as potentially measurable: EPA Method 6200

for Field Portable X-Ray Fluorescence Spectrometry lists the following elements

as being potentially measurable:

» Antimony (Sb)

» Arsenic (As)

» Barium (Ba)

» Cadmium (Cd)

» Calcium (Ca)

» Chromium (Cr)

» Cobalt (Co)

» Copper (Cu)

» Iron (Fe)

» Lead (Pb)

» Manganese (Mn)

» Mercury (Hg)

» Molybdenum (Mo)

» Nickel (Ni)

» Potassium (K)

» Rubidium (Rb)

» Selenium (Se)

2-10 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

» Silver (Ag)

» Strontium (Sr)

» Thallium (Tl)

» Thorium (Th)

» Tin (Sn)

» Titanium (Ti)

» Vanadium (V)

» Zinc (Zn)

» Zirconium (Zr)

XRF not effective for lithium, beryllium, sodium, magnesium, aluminum,

silicon, or phosphorus: The XRF cannot detect common elements that are

considered to be “light” elements, such as lithium, beryllium, sodium,

magnesium, aluminum, silicon, and phosphorus.

In practice, interference effects among elements can make some elements

“invisible” to the detector, or impossible to accurately quantify: In practice,

the performance of the XRF (as measured by detection limits and ability to

accurately quantify an element) is highly variable from element to element. One

of the factors contributing to variations in performance is the interference among

elements whereby the elevated presence of one element may mask the elevated

presence of another. A common example is arsenic being masked by the

presence of lead. Interference effects are real, element-specific, and at times

significant.

August 2008 2-11

Module 2 – Basic XRF Concepts XRF Web Seminar

How Is An XRF Calibrated?

Fundamental Parameters Calibration – calibration

based on known detector response properties,

“standardless” calibration, what is commonly done

Empirical Calibration – calibration calculated using

regression analysis and known standards, either site-

specific media with known concentrations or prepared,

spike standards

In both cases, the instrument will have a dynamic range

over which a linear calibration is assumed to hold.

2-9

Most, in not all, XRF vendors today are more than happy to help users develop

site-specific calibrations for their XRF applications. These can be particularly

important where site-specific matrix effects are of particular concern, and/or

when the element of interest is not one of the standard set used for factory

standardless calibrations.

It is important to remember that the XRF is no different than any other analytical

method. Properly calibrated, it will have a range of concentrations over which the

linear calibration is assumed to hold for any particular element. That range

typically runs from the instrument’s detection limits up to the percent range of

concentrations. One should not expect the XRF to accurately report

concentrations above its calibration range. In a standard laboratory the solution

to this problem is to dilute the sample. Unfortunately dilution is not an option with

a field-deployed XRF. The issue of calibration range is typically not a problem if

one is simply screening soils for concentrations above or below some decision-

making threshold. It can become an issue, however, if one is interested in

estimating the average concentration over an area using multiple XRF

measurements, and when some of those measurements include high levels of

contamination. It can also be an issue when one is trying to establish

comparability between an XRF result and a corresponding laboratory analysis,

and that comparison involves highly contaminated samples.

2-12 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

2-10

Dynamic Range a Potential Issue

No analytical method is

good over the entire range

of concentrations

potentially encountered

with a single calibration

XRF typically under-

reports concentrations

when calibration range

has been exceeded

Primarily an issue with

risk assessments

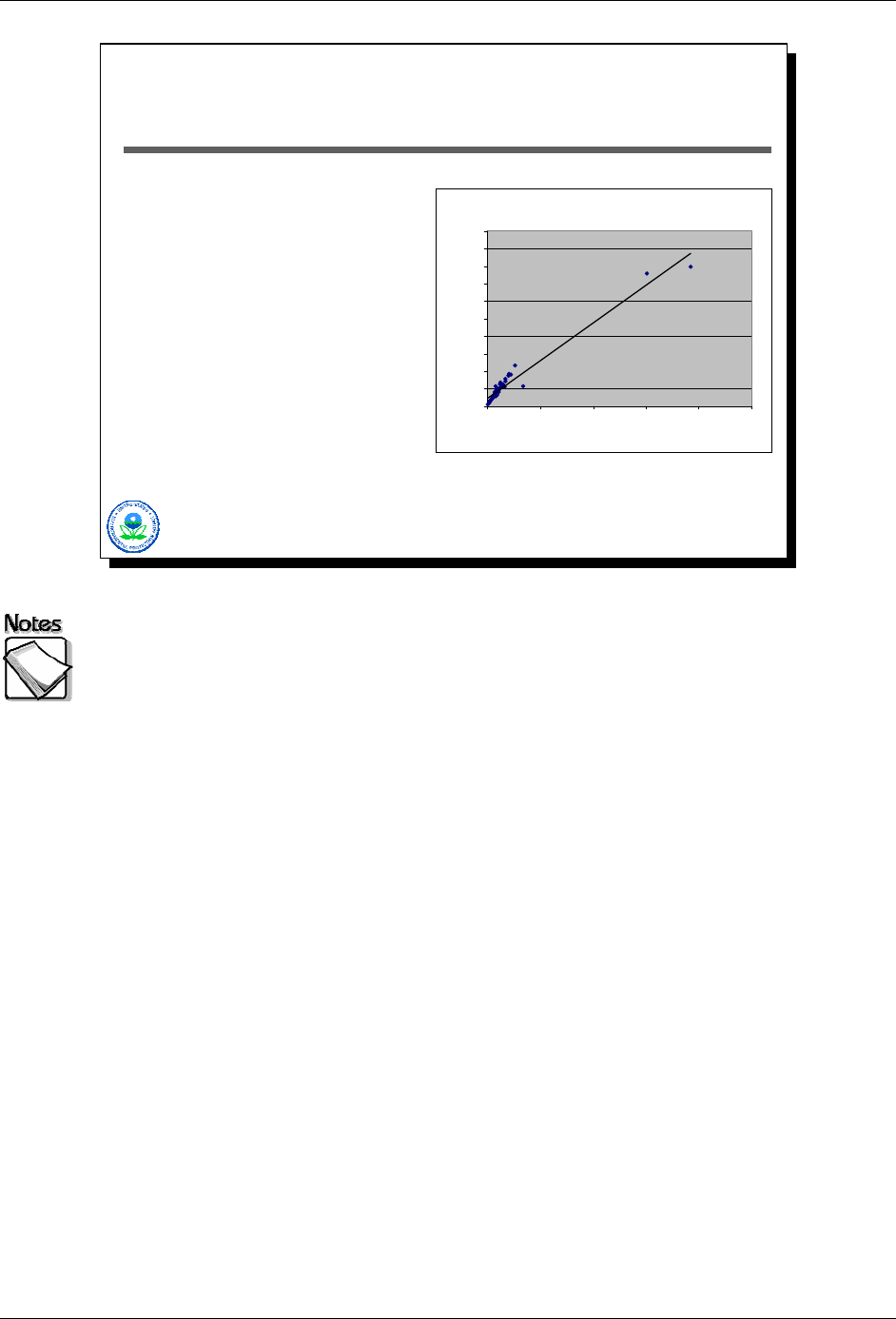

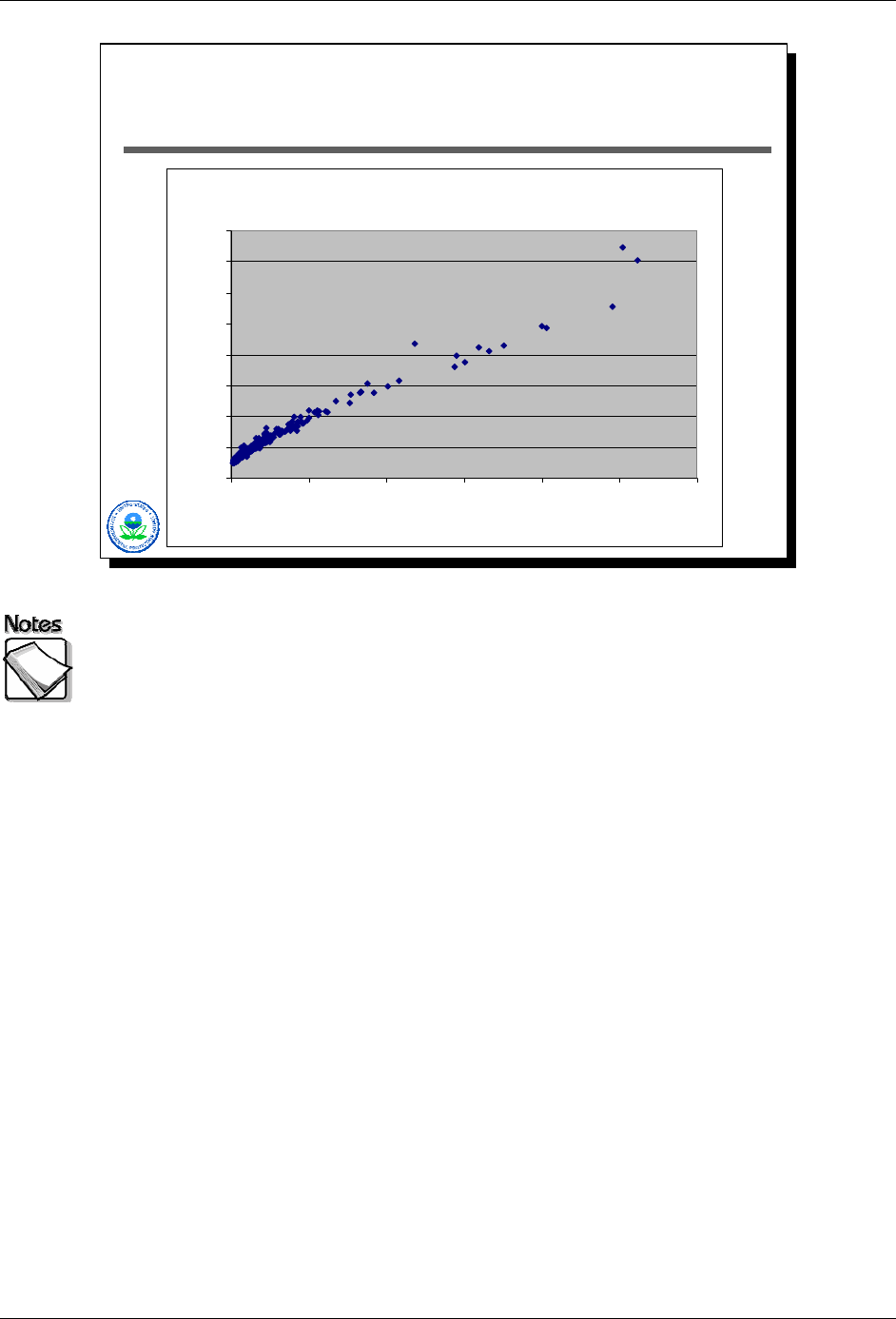

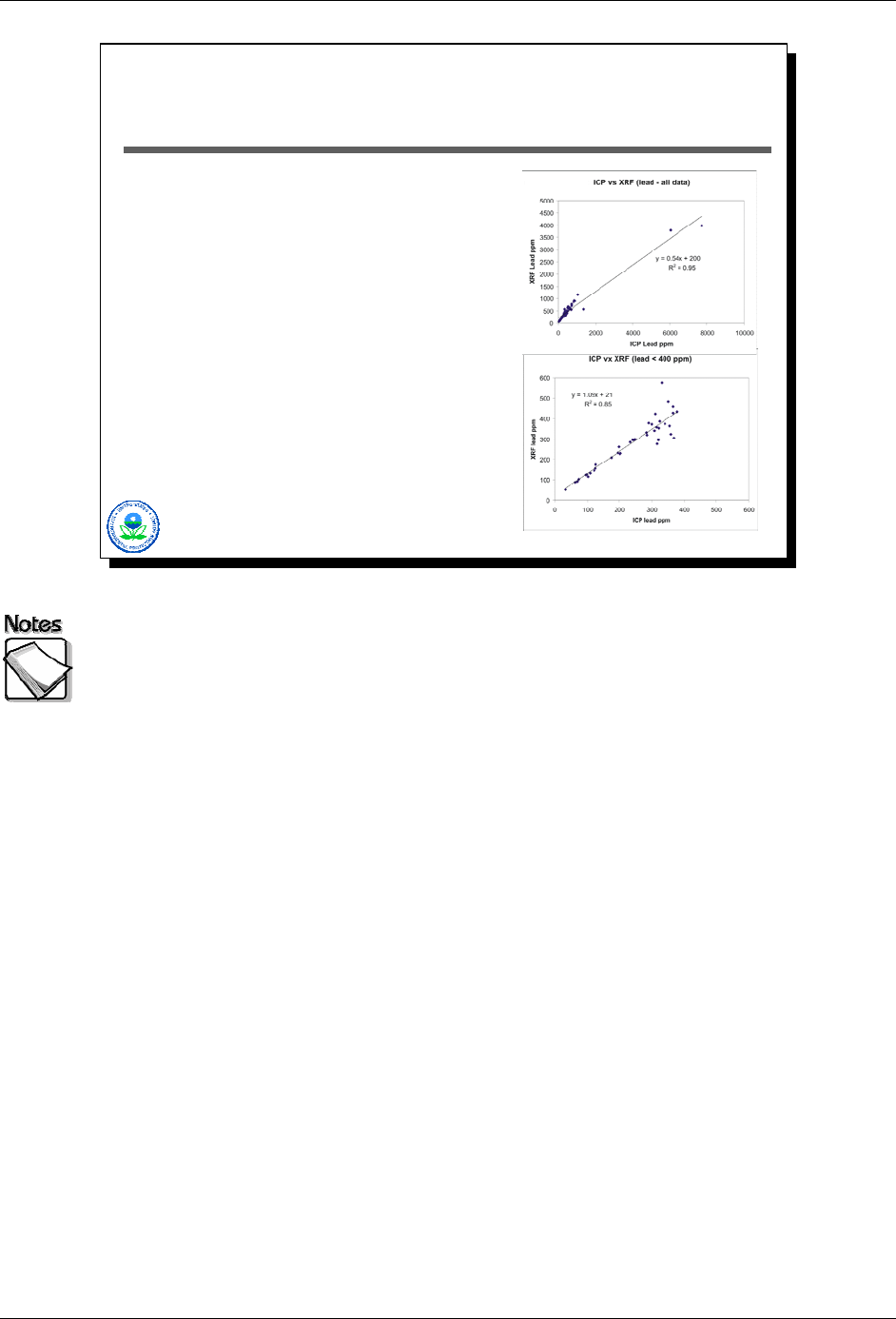

Figure 1: ICP vs XRF (lead - all data)

y = 0.54x + 200

R

2

= 0.95

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

0 2000 4000 6000 8000 10000

ICP Lead ppm

XRF Lead ppm

No analytical method is good over the entire range of concentrations

potentially encountered with a single calibration: As the graph shows, there

is good agreement between the XRF and ICP analysis at the lower end of the

concentration range but not at the higher end of the concentration range.

XRF typically underreports concentrations when calibration range has

been exceeded: As the graph shows, the XRF reports lower concentrations of

lead than the ICP analysis at concentrations above 6,000 parts per million (ppm).

Primarily an issue with risk assessments: This phenomenon is an issue

when the data are to be used in a risk assessment because underreporting

concentrations may underestimate the actual risk associated with the

contamination.

August 2008 2-13

Module 2 – Basic XRF Concepts XRF Web Seminar

Standard Innov-X Factory

Calibration List

Antimony (Sb) Iron (Fe) Selenium (Se)

Arsenic (As) Lead (Pb) Silver (Ag)

Barium (Ba) Manganese (Mn) Strontium (Sr)

Cadmium (Cd) Mercury (Hg) Tin (Sn)

Chromium (Cr) Molybdenum (Mo) Titanium (Ti)

Cobalt (Co) Nickel (Ni) Zinc (Zn)

Copper (Cu) Rubidium (Ru) Zirconium (Zr)

2-11

This slide shows the list of compounds available for the standard Innov-X factory

calibrations.

2-14 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

How Is XRF Performance Commonly

Defined?

Bias – does the instrument systematically under or over-

estimate element concentrations?

Precision – how much “scatter” solely attributable to

analytics is present in repeated measurements of the

same sample?

Detection Limits – at what concentration can the

instrument reliably identify the presence of an element?

Quantitation Limits – at what concentration can the

instrument reliably measure an element?

Representativeness – how representative is the XRF

result of information required to make a decision?

Comparability – how do XRF results compare with

results obtained using a standard laboratory technique?

2-12

How is XRF performance commonly defined: The following factors are used

to define how an XRF performs:

» Bias – does the instrument systematically under or over-estimate element

concentrations?

» Precision – how much “scatter” solely attributable to analytics is present in

repeated measurements of the same sample?

» Detection Limits – at what concentrations can the instrument reliably identify

the presence of an element?

» Quantitation Limits – at what concentrations can the instrument reliably

measure an element?

» Representativeness – how representative is the XRF result of information

required to make a decision?

» Comparability – how do XRF results compare with results obtained using a

standard laboratory technique?

The following slides will discuss precision, detection limits, and comparability in

more detail.

August 2008 2-15

Module 2 – Basic XRF Concepts XRF Web Seminar

Analytical Precision Driven By…

Measurement time – increasing measurement

time reduces error

Element concentration present – increasing

concentrations increase error

Concentrations of other elements present –as

other element concentrations rise, general

detection limits and errors rise as well

2-13

Measurement time: Measurement time affects precision. Increasing the

measurement time reduces error and increases precision.

Element concentration present: The amount of the element of concern affects

precision. Generally, increasing concentrations result in increased error and

decreased precision.

Concentrations of other elements present: The presence of other elements

affects precision. As the concentration of other elements rise, general detection

limits and errors rise, decreasing analytical precision.

2-16 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

2-14

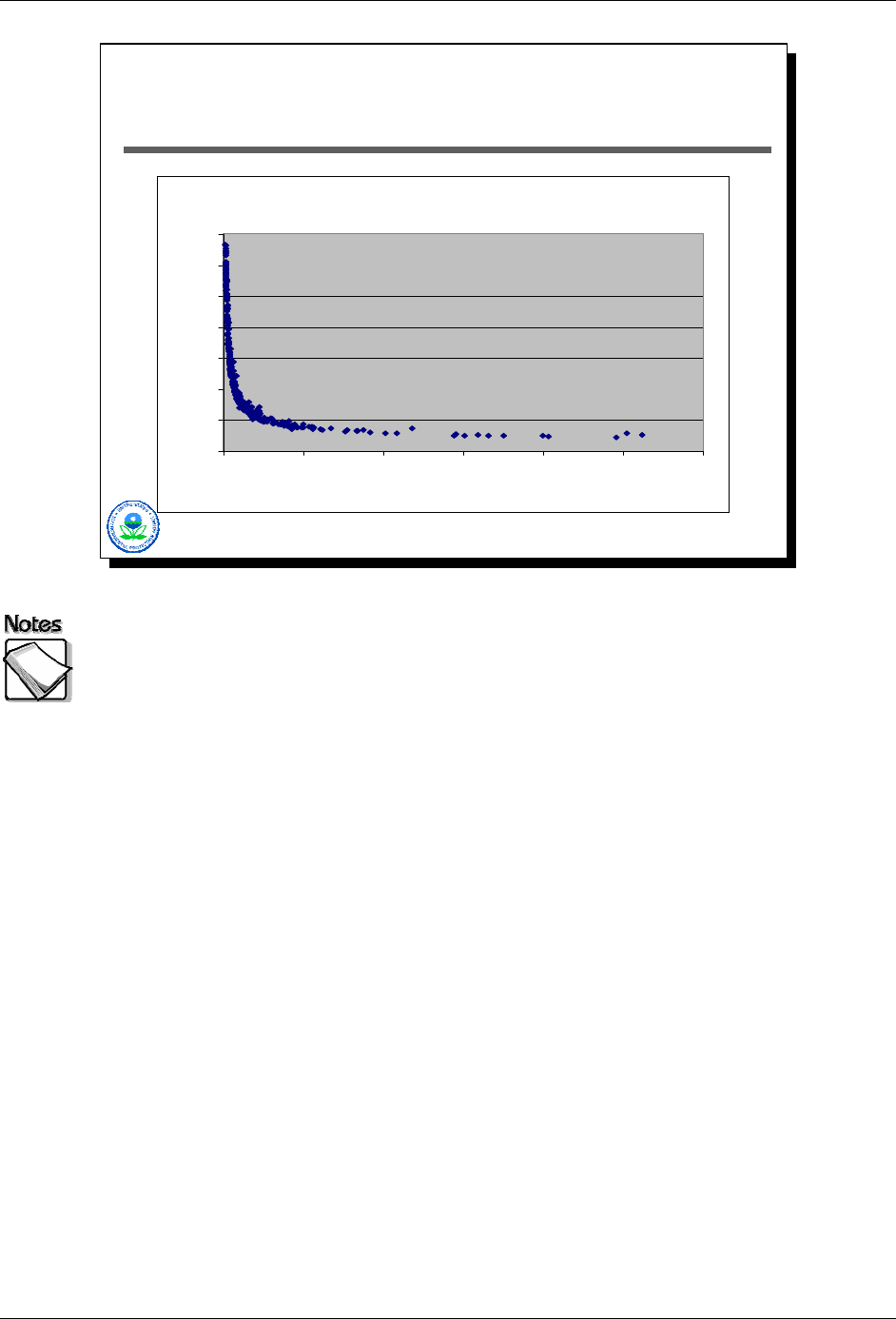

Lead Example: Concentration Effect

Reported Error vs. Lead Concentrations

0

10

20

30

40

50

60

70

80

0 500 1000 1500 2000 2500 3000

XRF Lead Concentrations (ppm)

Reported Error (ppm)

The next two slides show two graphs that illustrate the effects of concentrations

on reported measurement errors in the case of 434 lead measurements with an

XRF. In the first graph, the x-axis shows lead concentrations while the y-axis

shows their associated reported errors. One gets the general relationship that

one would expect: error grows as the square root of concentration. In other

words, to double the error one needs to quadruple the concentration.

Notice too that these relationships start to fall apart as XRF lead values become

high, reflecting the contribution of other sources of error to measurement error

(e.g., the presence of other elements that are very elevated).

August 2008 2-17

Module 2 – Basic XRF Concepts XRF Web Seminar

2-15

Lead Example: Concentration Effect

% Error vs. Lead Concentrations

0

5

10

15

20

25

30

35

0 500 1000 1500 2000 2500 3000

XRF Lead Concentrations (ppm)

% Error

This graph also illustrates the effects of concentrations on reported measurement

errors in the case of 434 lead measurements with an XRF. Percent error is

plotted as a function of concentration. Notice that % error is a maximum at the

detection limits of the instrument, and is never more than approximately 30%.

For lead values in the range of what is typically of interest (e.g., 400 ppm),

percent error is less than 5%. This is an important fact to keep in mind. The

expectation for standard laboratory analytical precision is less than 10%. In the

case of this XRF example, the XRF meets that expectation for lead values

greater than approximately 100 ppm. A general rule of thumb for any particular

element is that for concentrations that are10 times the XRF’s detection limit, the

analytical error of XRF measurements will be less than 10%.

2-18 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

XRF Detection Limit (DL)

Calculations

SW-846 Method 6200 defines DL as 3 X the

standard deviation (SD) attributable to the

analytical variability (imprecision) at a low

concentration

XRF “measures” by counting X-ray pulses

XRF instruments typically report DLs based on

counting statistics using the 3 X SD definition

SDs and associated DLs can also be calculated

manually from repeated measurements of a

sample (if concentrations are detectable to begin

with)

2-16

XRF detection limit (DL) calculations: Remember that relative error or percent

error (error divided by the concentration) falls as concentration increases. What

this means is that using this definition of detection limits, the percent error

associated with an XRF measurement will never be more than approximately

30%, and usually will be significantly less.

A common question people ask is what the detection limit is for a measurement

where the element of interest was detected and reported by the XRF. A common

mistake is for the detection limit to be estimated, in this case, by taking the error

of the measurement and multiplying the error by three. This can significantly

over-estimate the detection limits of the instrument. The reason is that analytical

error increases as concentrations increase. Consequently the error for a

quantifiable concentration will be greater than the error if the element had not

been present.

August 2008 2-19

Module 2 – Basic XRF Concepts XRF Web Seminar

2-17

The 3 Standard Deviation Concept

Frequency of XRF Responses When Element Not Present

Stdev = 5 ppm

Detection Limit:

15 ppm

99.87%

The graphic above illustrates the frequency of XRF responses when the element

is not present. Assume that a sample does not have an element present (or that

it is present at trace levels). If one were to take a measurement of the sample

with the XRF, the XRF would record a concentration present for that element just

because of the random nature of x-ray counting statistics. If one did a large

number of repeat measurements, one could generate a distribution or frequency

plot of those “random” concentrations such as is shown here, with a measurable

standard deviation. Notice that the frequency distribution is centered around

zero, indicating that this instrument is providing an unbiased estimate of the

concentration for the element of interest. Notice too that half the time the

instrument would report positive values, and half the time it would report negative

values…an important fact that will be discussed later. If one moves three

standard deviations up from zero and calls that the detection limit (consistent with

SW846 Method 6200), then almost 100% of the concentration values generated

when the element is not present would be less than the detection limit. In other

words, if the instrument records a result greater than this detection limit, then it is

very likely that in fact the element is present.

2-20 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

2-18

DL <> Reliable Detection

Stdev = 5 ppm

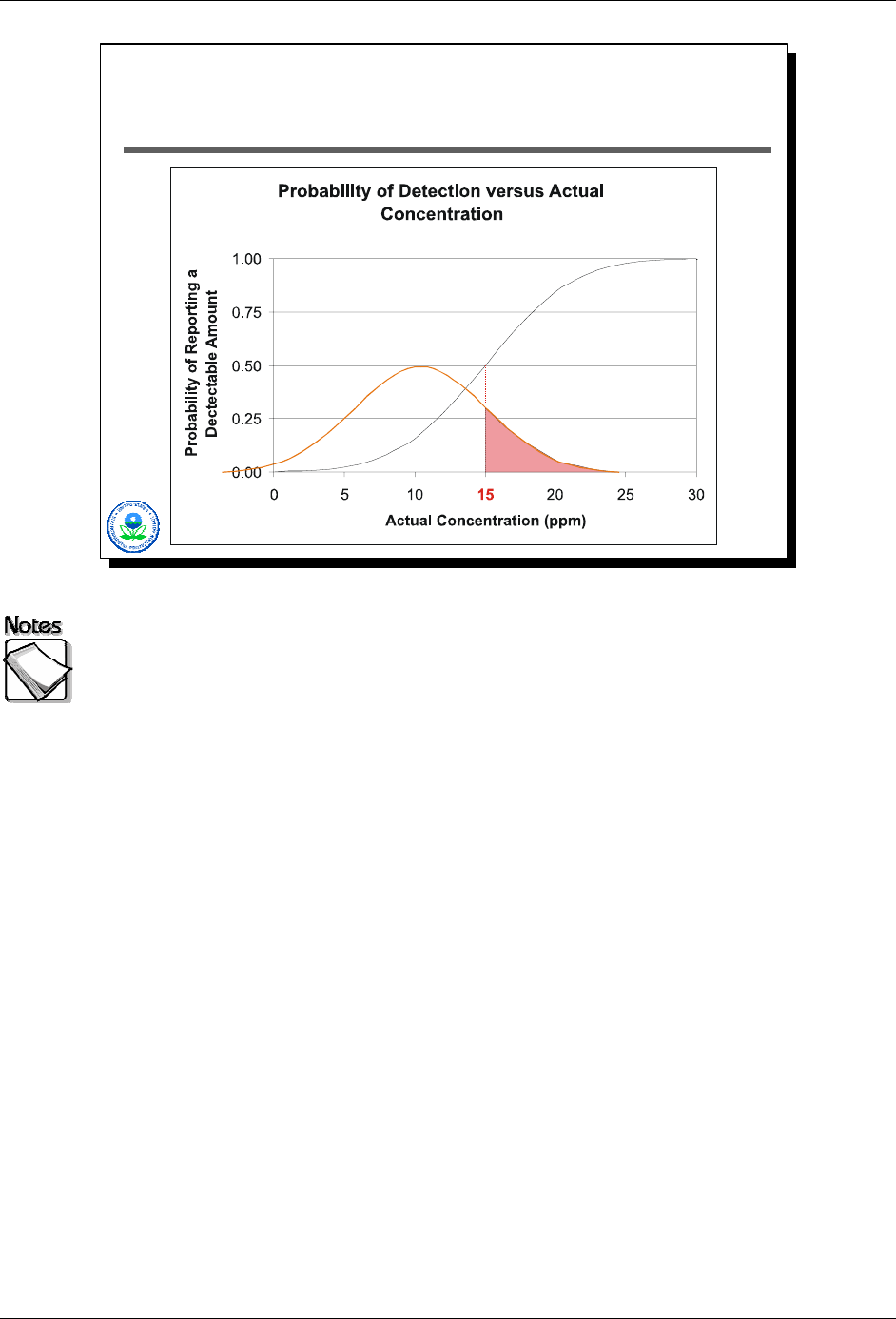

As defined and implemented, the detection limit for an XRF is not the same as

the concentration that can be reliably detected. The graphics on this and the

next two slides illustrate that fact. We start with the same scenario as the

previous slide, an element with a XRF detection limit of 15 ppm. In these slides,

the x-axis is actual concentration, while the y-axis is the probability the XRF will

detect the element. The three red bell-shaped frequency curves show what the

XRF response might be for three different actual concentrations (10 ppm, 15

ppm, and 20 ppm). The portion under the curves shaded red represents the

fraction of repeated measurements at that concentration that would have yielded

a result above the detection limit (15 ppm). As show in Slide 2-18 above, if the

actual concentration were 10 ppm, about a third of the measurements would

have yielded a “detection” (an XRF result > 15 ppm). The probability of reporting

a detection, as a function of actual concentration, is shown by the black S-

shaped curve.

August 2008 2-21

Module 2 – Basic XRF Concepts XRF Web Seminar

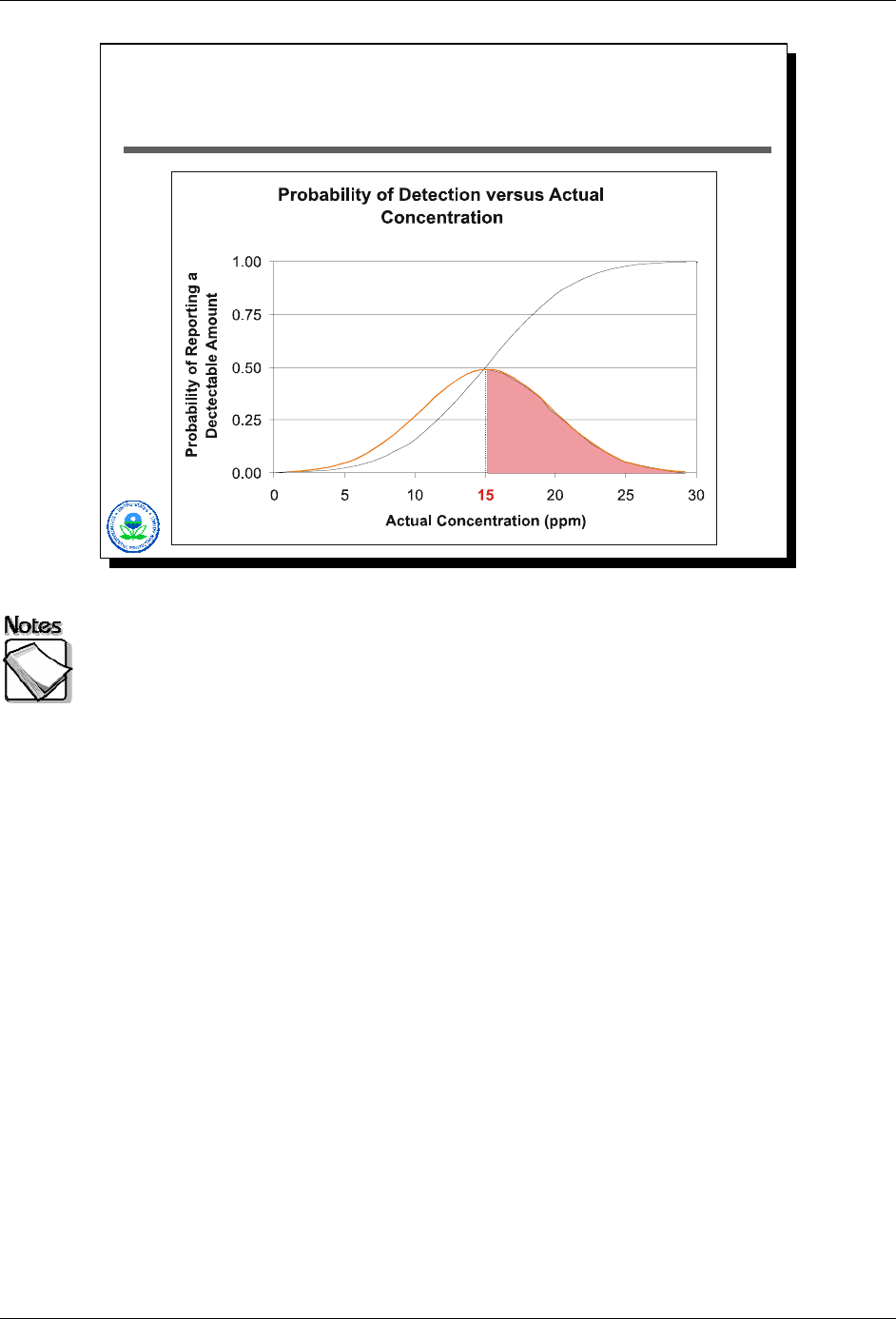

DL <> Reliable Detection

Stdev = 5 ppm

2-19

As shown in Slide 2-19 above, if the actual concentration were 15 ppm (at the

detection limit), the XRF would have detected the element only 50% of the time.

The probability of reporting a detection, as a function of actual concentration, is

shown by the black S-shaped curve.

2-22 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

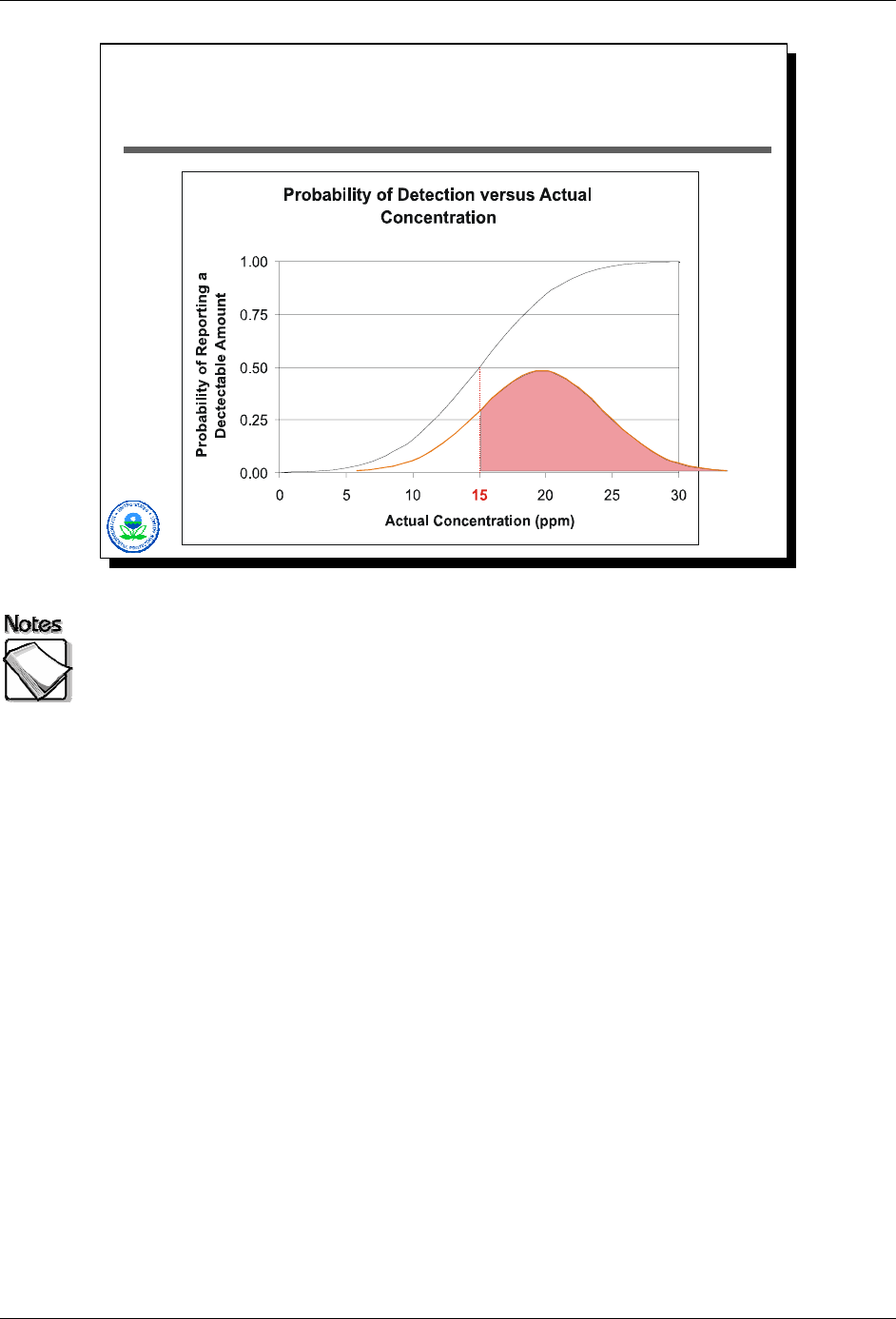

DL <> Reliable Detection

Stdev = 5 ppm

2-20

As shown in Slide 2-20 above, if the actual concentration was 20 ppm, the XRF

would have reported a detected value about two thirds of the time. In this

particular case, it is not until the actual concentration reaches 30 ppm (or twice

the DL) that the XRF will report a detectable value almost all of the time. The

probability of reporting a detection, as a function of actual concentration, is

shown by the black S-shaped curve.

August 2008 2-23

Module 2 – Basic XRF Concepts XRF Web Seminar

For Any Particular Instrument,

Detection Limits Are Influenced By…

Measurement time (quadrupling time cuts detection limits

in half)

Matrix effects

Presence of interfering or highly elevated contamination

levels

Consequently, the DL for any particular element will

change, sometimes dramatically, from one sample to the

next, depending on sample characteristics and operator

choices

2-21

Measurement time: The precision or reproducibility of a measurement will

improve with increasing measurement time. Increasing the count time by a factor

of 4 will provide 2 times better precision. Consequently increasing the count time

by a factor of 4 will cut detection limits by a factor of two. Of course, increasing

count time decreases sample throughput, so selecting the appropriate

measurement time is a trade-off between the desired detection limits and per-

sample measurement costs.

Matrix effects: Physical matrix effects result from variations in the physical

character of the sample. These variations may include such parameters as

particle size, uniformity, homogeneity, and surface condition. One way to reduce

error associated with variation in particle size is to grind and sieve all soil

samples to a uniform particle size. Differences in matrix effects can result in

differences in detection limits from one sample to the next.

Presence of interfering or highly elevated contamination levels: Chemical

matrix effects result from the differences in the concentrations of interfering

elements. These effects occur as either spectral interferences (peak overlaps) or

as x-ray absorption and enhancement phenomena. Both effects are common in

soils contaminated with heavy metals. For example, iron tends to absorb copper

x-rays, reducing the intensity of the copper measured by the detector, while

chromium will be enhanced at the expense of iron because the absorption edge

of chromium is slightly lower in energy than the fluorescent peak of iron. When

present in a sample, certain x-ray lines from different elements can be very close

in energy and, therefore, can cause interference by producing a severely

overlapped spectrum. The presence of interference effects will raise detection

limits.

2-24 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

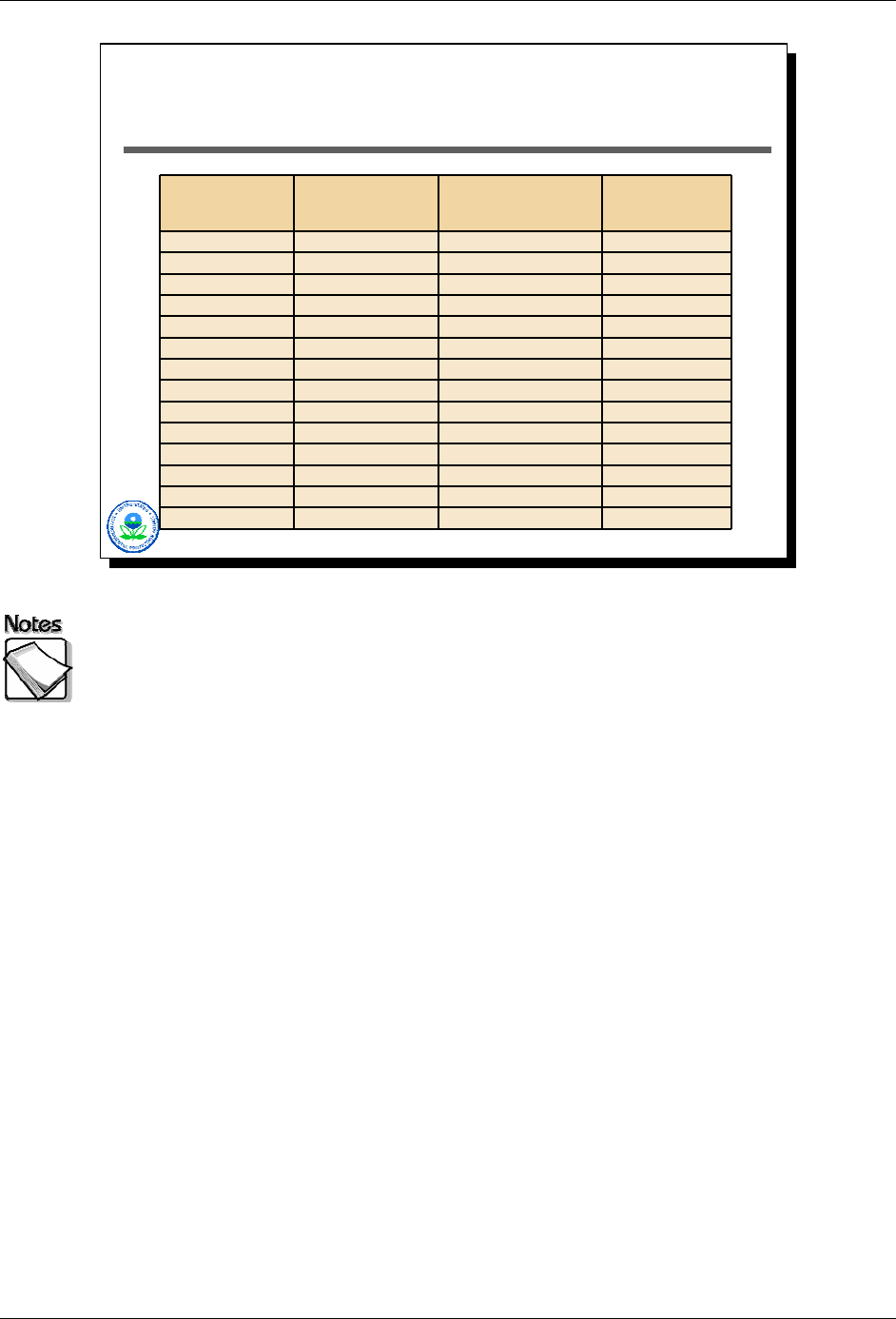

Examples of DL…

Analyte

Innov-X

1

120 sec acquisition

(soil standard –ppm)

Innov-X

1

120 sec acquisition

(alluvial deposits - ppm)

Innov-X

1

120 sec acquisition

(elevated soil -ppm)

Antimony (Sb) 61 55 232

Arsenic (As) 6 7 29,200

Barium (Ba) NA NA NA

Cadmium (Cd) 34 30 598

Calcium (Ca) NA NA NA

Chromium (Cr) 89 100 188,000

Cobalt (Co) 54 121 766

Copper (Cu) 21 17 661

Iron (Fe) 2,950 22,300 33,300

Lead (Pb) 12 8 447,000

Manganese (Mn) 56 314 1,960

Mercury (Hg) 10 8 481

Molybdenum (Mo) 11 9 148

Nickel (Ni) 42 31 451

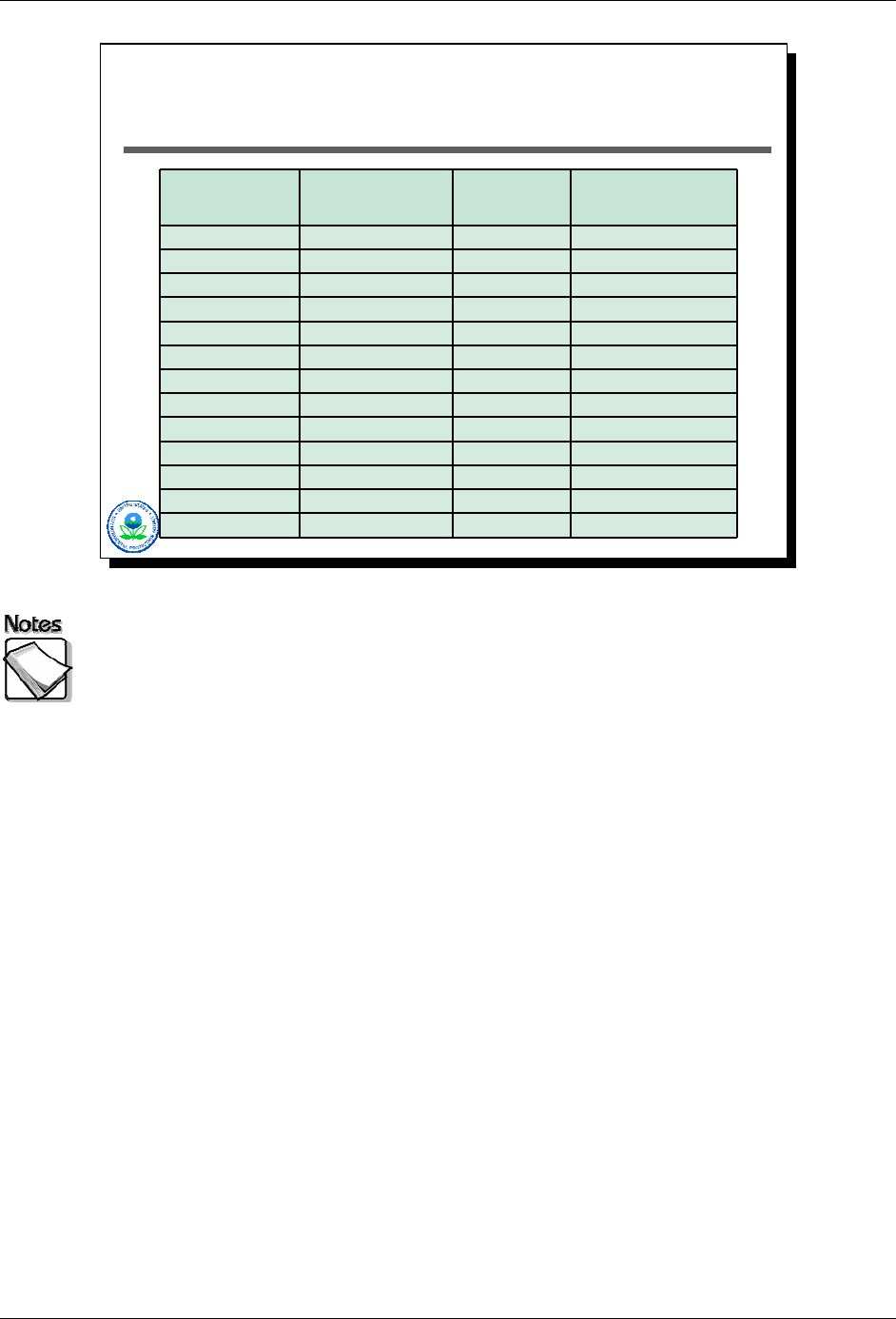

2-22

The table illustrates the fact that detection limits can change dramatically from

sample to sample. Here we see three different sets of results from the same

Innov-X unit, in each case collected with a 120-second acquisition time. The

bold numbers in this table are actually quantified values (i.e., detects), while the

plain text numbers are detection limits for elements that were not detectable.

Results for three different samples are presented. The first is for a spiked matrix

(the spiked element is not present in this table). The second is for a background

soil sample taken from alluvial deposits. The third is for a highly contaminated

sample taken beneath a leaking waste sewer line at a chemical facility.

The effect of highly elevated lead and chromium on the detection limits for other

elements is severe. The detection limit for mercury jumps from around 10 ppm to

almost 500 ppm, a 50 times factor change.

One other note about these data. The concentration levels reported for

chromium and lead for the contaminated sample fall outside the calibrated range.

These values would and should be taken with a large dose of skepticism…the

levels of lead and chromium in this sample are undoubtedly extremely high, but

the ability of the XRF to accurately quantify them at these levels would be very

suspect.

August 2008 2-25

Module 2 – Basic XRF Concepts XRF Web Seminar

To Report, or Not to Report:

That is the Question!

Not all instruments/software allow the reporting of

XRF results below detection limits

For those that do, manufacturer often

recommends against doing it

Can be valuable information if careful about its

use…particularly true if one is trying to calculate

average values over a set of measurements

2-23

Not all instruments/software allow the reporting of XRF results below

detections limits: Some instruments and associated software do not allow the

reporting of measurement results that are below detection limits.

For those that do, manufacturer ofter recommends against doing it: For

those instruments that do allow reporting of results below detection limits, the

manufacturer usually advises against it. Within the chemistry analytical world,

the approach has been to not report values less than detection limits. Within the

radionuclide analytical world, the approach has been to report values less than

detection limits. The XRF is an analytical technique that has its roots in the

radionuclide world (e.g., gamma and alpha spectroscopy), but has applications to

the chemical world (e.g., elemental metals).

Can be valuable information if careful about its use . . . particularly true if

one is trying to calculate average values over a set of measurements:

Values below detection limits can be useful when calculating average values

over a set of measurements. If the instrument’s calibration is unbiased for low

levels of the element of interest, using measured values below the instrument’s

detection limits can yield more accurate assessments of average concentrations

that flagging readings as non-detects and substituting some arbitrary value such

as the detection limit, or half the detection limit, in average value calculations.

Great care and full disclosure are necessary when using values below detection

limits.

2-26 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

XRF Data Comparability

Comparability usually refers to comparing XRF

results with standard laboratory data

Assumption is one has samples analyzed by both

XRF and laboratory

Regression analysis is the ruler most commonly

used to measure comparability

SW-846 Method 6200: “If the r

2

is 0.9 or

greater…the data could potentially meet definitive

level data criteria.”

2-24

Comparability usually refers to comparing XRF results with standard

laboratory data: The comparability of the XRF analysis is determined by

submitting XRF-analyzed samples for analysis at a laboratory. The XRF results

are then compared with the laboratory results.

Assumption is one has samples analyzed by both XRF and laboratory: The

confirmatory samples must be splits of well homogenized sample material. The

confirmatory samples should be selected from the lower, middle, and upper

range of concentrations measured by the XRF. They should also include

samples with element concentrations at or near the site action levels.

Regression analysis is the ruler most commonly used to measure

comparability: The results of the confirmatory analysis and XRF analyses are

usually evaluated with a least squares linear regression analysis.

SW-846 Method 6200: “If the r

2

is 0.9 or greater . . . the data could

potentially meet definitive level data criteria.”: Method 6200 states that the

method of confirmatory analysis must meet the project and XRF measurement

data quality objectives. The method also suggests that the r

2

for the results

should be 0.7 or greater for the XRF data to be considered screening level data.

Finally, the method states that if the r

2

is 0.9 or greater and inferential statistics

indicate the XRF data and the confirmatory data are statistically equivalent at a

99 percent confidence level, the data could potentially meet definitive level data

criteria.

August 2008 2-27

Module 2 – Basic XRF Concepts XRF Web Seminar

2-25

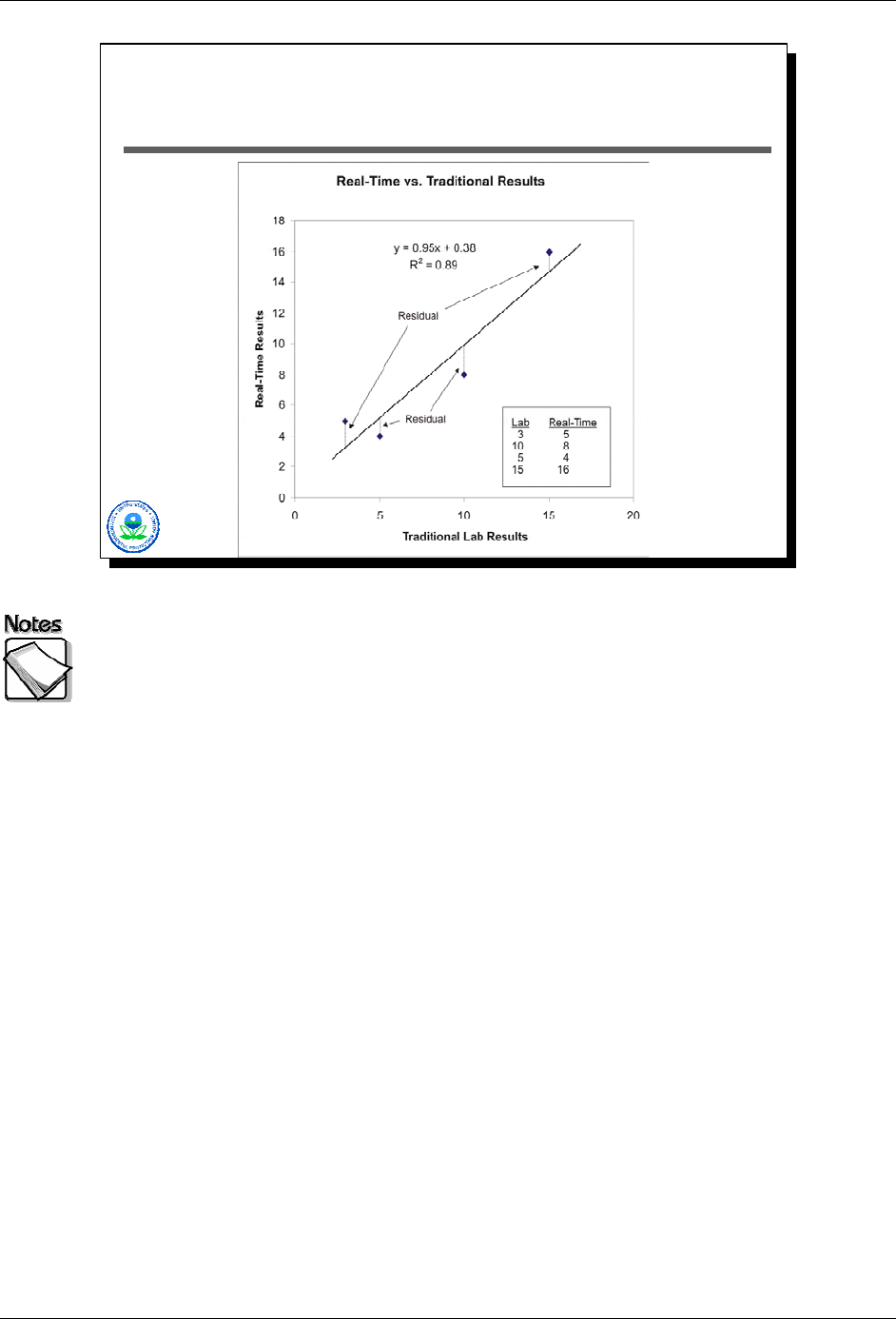

What is a Regression Line?

The scatter-plot in this slide illustrates how a regression analysis works. The

data in the lower-right table represents our collaborative data set: four samples,

with each having both a traditional laboratory result and a real-time result (e.g.

XRF). Plotting these data give us the scatter-plot shown. Assuming there’s a

linear relationship between results generated by the laboratory and results

generated by the real-time technique, the question is finding that linear

relationship.

The line shown represents the results from a regression using these data. The

regression line represents the “best fit” line. “Best fit” here is defined as the line

that minimizes the sum of the squared residuals. A residual is the vertical

distance separating a regression line and a data point.

2-28 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

Regression Terminology

Scatter Plot: graph showing paired sample results

Independent Variable: x-axis values

Dependent Variable: y-axis values

Residuals: difference between dependent variable result

predicted by regression line and observed dependent

variable

Adjusted R

2

: a measure of goodness-of-fit of regression

line

Homoscedasticity/Heteroscedasticity: Refers to the size

of observed residuals, and whether this size is constant

over the range of the independent variable

(homoscedastic) or changes (heteroscedastic)

2-26

Regression terminology: The following are regression terms:

» Scatter Plot – graph showing paired sample results

» Independent Variable – x-axis values, usually the lab result

» Dependent Variable – y-axis values, usually the XRF result

» Residuals – difference between dependent variable result predicted by

regression line and observed dependent variable

» Adjusted R

2

– a measure of goodness-of-fit of regression line

» Homoscedasticity/Heteroscedasticity – refers to the size of observed

residuals, and whether this size is constant over the range of the independent

variable (homoscedastic) or changes (heteroscedastic)

August 2008 2-29

Module 2 – Basic XRF Concepts XRF Web Seminar

2-27

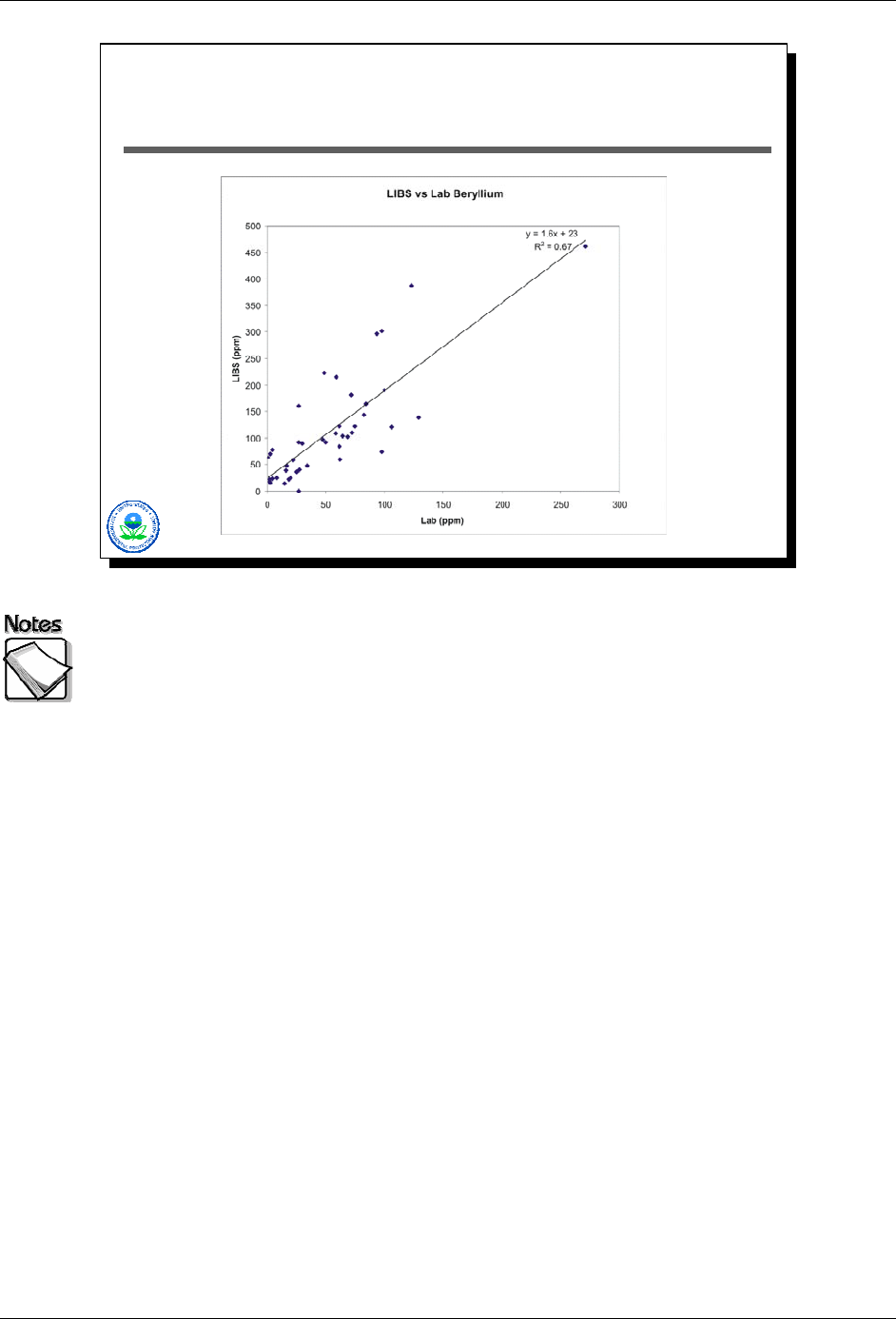

Heteroscedasticity is a Fact of Life

for Environmental Data Sets

Heteroscedasticity is unfortunately a fact-of-life for environmental collaborative

data sets. The LIBS/laboratory scatter-plot illustrates the concept of

heteroscedasticity. We can fit a regression line to these data, with the resulting

line and its equation shown. The orange lines bracketing the regression line

above and below given a sense for how the size of residuals change as

concentrations increase. For low concentrations, the scatter-plot points are

tightly clustered around the regression line, giving rise to relatively small

residuals. As concentrations increase, the “scatter” of points around the line

steadily increases. The result is that residuals for higher-concentration points are

much larger than what they are for lower concentration values. This increasing

residual size as concentrations increase is called heteroscedasticity.

The concept is important because regression analyses often include UCL lines or

UTL lines that bracket the regression line. The problem with this is that UCL and

UTL calculations derived from a regression analysis are only valid if the

underlying data are homoscedastic…which environmental collaborative data

never are. The warning: beware of trying to extract too much from a regression

analysis’s results.

There is a simple physical explanation for heteroscedasticity in environmental

collaborative data…analytical error tends to increase as concentrations increase.

2-30 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

Appropriate Regression Analysis

Based on paired analytical results, ideally from

same sub-sample

Paired results focus on concentration ranges

pertinent to decision-making

Non-detects are removed from data set

Best regression results obtained when pairs are

balanced at opposite ends of range of interest

2-28

Based on paired analytical results, ideally from same sub-sample: Such an

analysis should be based on paired results, ideally with the analytical work done

on the same sub-sample where possible to minimize the effects of sample

preparation. Poor comparability results are often the result of poorly prepared

samples and not analytical issues.

Paired results focus on concentration ranges pertinent to decision-making:

The paired results should focus on the concentration range pertinent to decision-

making. Often times field analytical methods have a more limited dynamic range

within which they provide accurate results. This means that it is unreasonable to

expect a good, strong linear relationship for two methods over the complete

range of concentrations (which may span several orders of magnitude) present at

a site. What is important is to determine whether such a relationship exists over

the range in which making decisions is important.

Non-detects are removed from data set: Non-detects should be removed from

a regression analysis because they will skew regression results.

Best regression results obtained when pairs are balanced at opposite ends

of the range of interest: The best regression results are obtained when the

data used are balanced, i.e., half are at the lower end of interest, and half are at

the higher end of interest. WARNING: unbalanced data sets (i.e., data sets

where most of the points are clustered at the low end with one or two high value)

will yield unstable and likely misleading regressions.

August 2008 2-31

Module 2 – Basic XRF Concepts XRF Web Seminar

Evaluating Regression Performance

No evidence of inexplicable “outliers”

Balanced data sets

No signs of correlated residuals

High R

2

values (close to 1)

Constant residual variance (homoscedastic)

2-29

No evidence of inexplicable outliers: There should be no evidence of outliers.

Outliers are points that clearly fall well away from the regression line and appear

to be different than the rest.

Balanced data sets: Data sets should be balanced.

No signs of correlated residuals: There should be no signs of correlated

residuals. Correlated residuals refer to the situation where a group of points

consistently fall above or below the regression line.

High R

2

values (close to 1): A good regression should have a high R

2

value,

preferably close to 1 (will range between 0 and 1).

Constant residual variance (homoscedastic): A good regression should also

have constant residual variance across the concentration range, or in other

words the data should be homoscedastic. Unfortunately for environmental

collaborative data sets, this is never the case.

2-32 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

Example: XRF and Lead

Full data set:

» Wonderful R

2

» Unbalanced data

» Correlated residuals

» Apparently poor calibration

Trimmed data set:

» Balanced data

» Correlation gone from residuals

» Excellent calibration

»R

2

drops significantly

2-30

Here’s an example based on XRF analyses of lead in soil samples. The top

graphic shows a scatter plot based on the complete data set collected. The

regression line has a wonderful R

2

value, but has several obvious visual

deficiencies. These include unbalanced data (most of it clustered at the low end

with only two points at the high end), correlated residuals, and what appears to

be a poor calibration for the XRF based on the slope of the line.

The second data set has had its data trimmed to include only those

concentrations that fall within the range truly of interest from a decision-making

perspective. These data are balanced across the concentration range of interest.

The correlations are gone from the residuals. The slope corresponds to what

one would expect from a calibrated XRF. Note that the R

2

value is actually less,

though, then the first example, even though the second regression is clearly

superior, underscoring the problems with simply using R

2

values as a measure of

regression performance and hence field analytic data quality and usability.

Also, in the second scatter plot the spread of the data around the line increases

as concentrations increase. This is called heteroscedasticity, and indicates that

the variance of the data is not constant over the range of observed

concentrations. The presence of heteroscedasticity is a given in environmental

data, and complicates the interpretation of regression results. Therefore,

interpreting UCLs and UTLs for regression lines when heteroscedasticity is

present should be done very carefully.

August 2008 2-33

Module 2 – Basic XRF Concepts XRF Web Seminar

Converting XRF Data for Risk

Assessment Use

Purpose: making XRF data “comparable” to lab data for

risk assessment purposes

To consider:

» Need for “conversion” may be an indication of a bad

regression

» XRF calibrations not linear over the range of

concentrations potentially encountered

» Extra variability in XRF data not an issue (captured in

UCL calculations when estimating EPC)

» Contaminant concentration distributions are typically

skewed… lots of XRF data may provide a better

UCL/EPC estimate than a few lab results even if the

regression is not great

2-31

Purpose: Some times XRF data are “converted” using a regression line to make

them “comparable” to laboratory data. One might do this if one wants to pool the

XRF data with lab data for risk assessment purposes.

To consider: Before “transforming” XRF data in this fashion, the following

should be considered:

» Need for “conversion” may be an indication of a bad regression

» XRF calibration are not linear over the range of concentrations potentially

encountered

» Extra variability in XRF data should not be an issue (captured in upper

concentration limit (UCL) calculations when estimating the exposure point

concentration (EPC))

» Contaminant concentration distributions are typically skewed . . . a large

volume of XRF data may provide a better UCL/EPC estimate than a few

laboratory results even if the regression is not great.

2-34 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

A Cautionary Example…

Four lab lead results: 20, 24, 86, and 189 ppm

ProUCL 95%UCL Calculations:

»Normal: 172 ppm

»Gamma: 434 ppm

»Lognormal: 246 – 33,835 ppm

»Non-parametric: 144 – 472 ppm

Four samples are not enough to either

understand the variability present, or the

underlying contamination distribution

2-32

This example shows that four samples are not enough to either understand the

variability present, or the underlying contamination distribution, no matter how

“high quality” the laboratory data are. If the action level for this site were 400

ppm, the decision about whether the area posed a risk or not would be

ambiguous. A larger volume of measurements, even if they were from an XRF

with analytical quality not quite as good as the lab’s, would provide a better

understanding of variability and contaminant distribution, and consequently a

better UCL estimate, assuming the XRF was properly calibrated for the element

of interest.

August 2008 2-35

Module 2 – Basic XRF Concepts XRF Web Seminar

2-33

Will the “Definitive” Data Please

Stand Up?

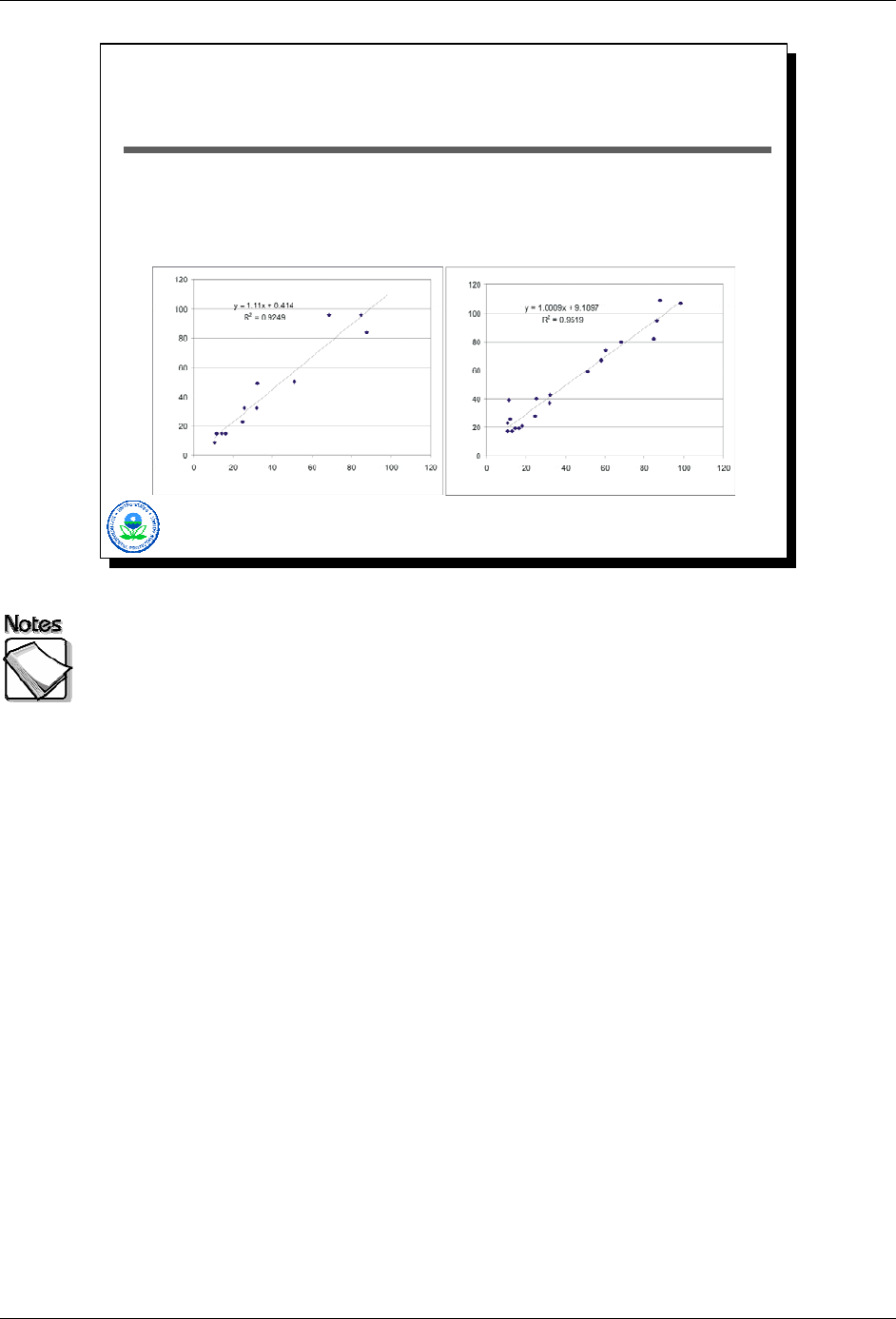

One of these scatter plots shows the results of arsenic from two different

ICP labs, and the other compares XRF and ICP arsenic results.

Which is which?

These two scatter plots show paired data results for arsenic. In one case,

samples first analyzed by XRF were then sent off for ICP analyses. In the other

case, the same sample was split and sent for ICP analyses to two different labs.

Which of these two corresponds to the ICP/ICP comparison, and which to the

XRF/ICP comparison?

The answer is that the scatter plot on the right compares XRF to ICP, while the

scatter plot on the left shows ICP versus ICP results for two different labs for the

same set of samples.

The take home point is quite simple. Traditional analyses are often treated as

though they are “definitive” and free from error. When the results of an

alternative analysis such as an XRF are compared to those from a traditional lab,

any differences observed are attributed to poor performance on the alternative

analysis’s part. The reality is not so simple. Traditional analyses also include

“errors” that need to be recognized.

2-36 August 2008

2-34

XRF Web Seminar Module 2 – Basic XRF Concepts

Definitive Data, Please Stand Up!

2-34

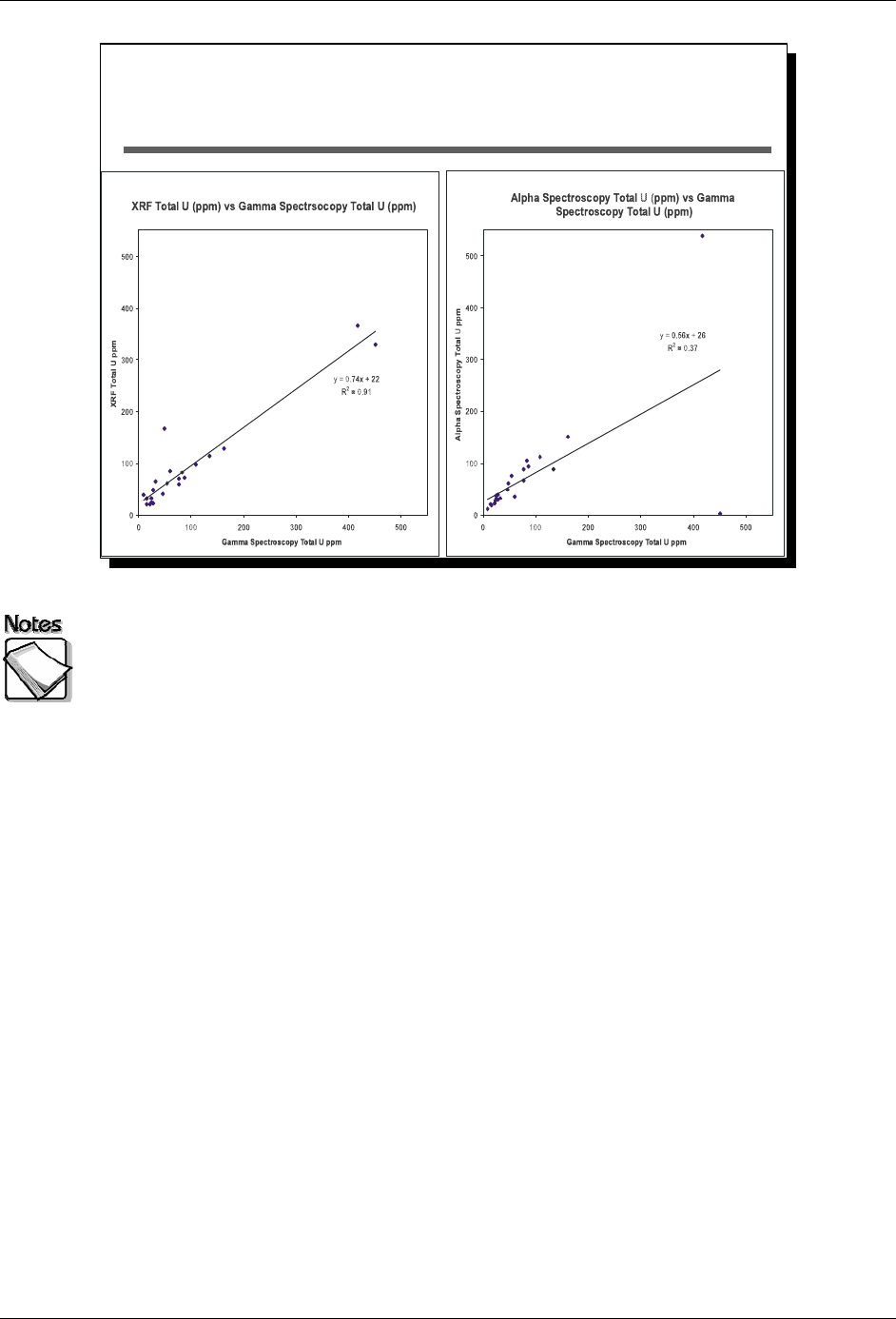

This slide shows results from a set of samples analyzed with three different

methods for uranium, via XRF (very limited sample preparation), gamma

spectroscopy (sample preparation, but no extraction), and alpha spectroscopy

(sample preparation with extraction required). The plot on the left compares XRF

and gamma spectroscopy data with a resulting R

2

of 0.91. The plot on the right

compares alpha spectroscopy and gamma spectroscopy data with a resulting R

2

of 0.37. Both gamma spectroscopy and alpha spectroscopy are well-established

methods for measuring uranium in soils. In this particular case, if the XRF had

just been compared to alpha spectroscopy results, the likely conclusion would

have been that there were performance problems with the XRF. The availability

of gamma spectroscopy data as well helped to identify alpha spectroscopy as the

problem for at least two of the samples.

August 2008 2-37

Module 2 – Basic XRF Concepts XRF Web Seminar

Take-Away Comparability Points

Standard laboratory data can be “noisy” and are

not necessarily an error-free representation of

reality

Regression R

2

values are a poor measure of

comparability

Focus should be on decision comparability, not

laboratory result comparability

Examine the lab duplicate paired results from

traditional QC analysis - The split field vs. lab

regression cannot be expected to be better than

the lab’s duplicate vs. duplicate regression

2-35

Standard laboratory data can be “noisy” and are not necessarily an error-

free representation of reality: It is a mistake to believe that standard laboratory

data are free of errors. This can be seen when laboratory analyses from two

different laboratories are compared to one another in the same way that XRF and

laboratory data are compared.

Regression R

2

values are a poor measure of comparability: Regression

performance should be judged using a number of factors, not just the R

2

value.

Focus should be on decision comparability, not laboratory result

comparability: Decision comparability judges whether or not data is suitable for

the decision at hand. XRF data may be suitable for decisions about whether an

action level has been exceeded or for calculating UCL/EPC even when the

regression is not perfect.

Examine the lab duplicate paired results from traditional QC analysis:

Frequently the regression from duplicate paired results is poor. It is

unreasonable to expect the split field (XRF) versus laboratory regression to be

better than the laboratory’s duplicate versus duplicate regression.

2-38 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

What Affects XRF Performance?

Measurement time – the longer the

measurement, the better the precision

Contaminant concentrations – potentially

outside calibration ranges, absolute error

increases, enhanced interference effects

Sample preparation – the better the sample

preparation, the more likely the XRF result will be

representative

(continued)

2-36

Measurement time: The longer the measurement time or count time, the better

the precision will be.

Contaminant concentrations: Contaminant concentrations may be outside of

the calibration ranges. Other contaminants may cause interference effects.

Sample preparation: The better the sample preparation, the more

representative the XRF results will be of actual conditions.

August 2008 2-39

Module 2 – Basic XRF Concepts XRF Web Seminar

What Affects XRF Performance?

Interference effects – the spectral lines of

elements may overlap

Matrix effects – fine versus coarse grain

materials may impact XRF performance, as well

as the chemical characteristics of the matrix

Operator skills – watching for problems,

consistent and correct preparation and

presentation of samples

2-37

Interference effects: The spectral lines of elements may overlap distorting

results for one or more elements.

Matrix effects: Physical matrix effects, such as fine versus course grain

materials, may impact XRF performance. In addition, chemical characteristics of

the matrix may also impact XRF performance.

Operator skills: The level of operator skill can affect XRF performance. The

operator should watch for problems and should practice consistent and correct

preparation and presentation of samples.

2-40 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

What Are Common XRF

Environmental Applications?

In situ and ex situ analysis of soil samples

Ex situ analysis of sediment samples

Swipe analysis for removable contamination on

surfaces

Filter analysis for filterable contamination in air

and liquids

Lead-in-paint applications

2-38

August 2008 2-41

Module 2 – Basic XRF Concepts XRF Web Seminar

Recent XRF Technology

Advancements…

Miniaturization of electronics

Improvements in detectors

Improvements in battery life

Improved electronic x-ray tubes

Improved mathematical algorithms for

interference corrections

Bluetooth, coupled GPS, connectivity with PDAs

and tablet computers

2-39

Recent XRF technology advancements: The following advancements in XRF

technology have improved the performance of the technology:

» Miniaturization of electronics – this has made the instruments more portable

» Improvements in detectors – with a corresponding lowering of detection limits

» Improvements in battery life – which increases sample throughput by

reducing instrument downtime and improves general field application

» Improved electronic x-ray tubes – which improves performance of the units

» Improved mathematical algorithms for interference corrections – which

expands the applicability of the technology

» Bluetooth, coupled GPS, connectivity with PDAs and tablet computers –

which enhances data collection, management, and storage

2-42 August 2008

XRF Web Seminar Module 2 – Basic XRF Concepts

…Contribute to Steadily Improving

Performance

Analyte

DL in Quartz Sand by

Method 6200

(600 sec – ppm)

TN 900 (60 to

100 sec) – ppm

Innov-X

1

120 sec acquisition

(soil standard – ppm)

Antimony (Sb) 40 55 61

Arsenic (As) 40 60 6

Barium (Ba) 20 60 NA

Cadmium (Cd) 100 NA 34

Chromium (Cr) 150 200 89

Cobalt (Co) 60 330 54

Copper (Cu) 50 85 21

Iron (Fe) 60 NA 2,950

Lead (Pb) 20 45 12

Manganese (Mn) 70 240 56

Mercury (Hg) 30 NA 10

Molybdenum (Mo) 10 25 11

Nickel (Ni) 50 100 42

2-40

This last table shows the results of XRF technology improvements over the

years. The first data column shows XRF detection limits as reported in Method

6200 in the best of conditions - quartz sand with a 600 second acquisition. The

second column shows the performance of a TN 900 XRF in the mid to late 1990s

(the table containing these results is dated 1998) with a 60 to 100 second

acquisition. One would expect these values to be less than half of what is

reported if a 600 second acquisition time had been used. The last column shows

data collected with an Innov-X unit in 1996 for a spiked soil standard (the spiking

element is not present in this table). Results in bold indicate actual measured

data. Plain text results are reported detection limits. The detection limit

differences are marked for a number of samples. For example, in the case of

arsenic the Innov-X detection limit is one tenth that of the TN 900 back in the

1990s. This improvement is not vendor-specific…in fact all vendors of portable

XRF technologies have made significant strides in improving instrument

performance in the last decade. One would expect those improvements to

continue and be reflected in falling detection limits and better handling of

interference effects.

August 2008 2-43

Module 2 – Basic XRF Concepts XRF Web Seminar

2-41

Q&A – If Time Allows

2-44 August 2008